If you decide to proceed, they'll set you up with a dedicated move coordinator. They recommend starting the moving process early by decluttering and organizing items to ensure a smoother move. This seasoned group of professionals is adept at handling all aspects of relocation, from meticulous planning and packing to safe transportation and setup in the new location.

From packing delicate items with the utmost care to securing furniture for transit, BBX Moving prioritizes your items' safety every step of the way. In the unfortunate event that a claim needs to be filed, the company guides its clients through every step, providing support and ensuring a swift resolution. BBX Moving doesn't just offer low prices; they deliver value. When you compare their pricing with other service providers in Richmond, it becomes clear that BBX Moving isn't just affordable; it's strategically priced to give you the best value for your money.

Without the overhead costs associated with national chains, they can provide more cost-effective solutions without compromising on quality. They've built a reputation in Richmond for not just meeting, but exceeding customer expectations. After ensuring that each item is expertly packed, BBX Moving also offers secure storage options, complete with specialized moving equipment, to safeguard your belongings until you're ready for them. BBX Moving suggests making these updates at least two weeks before moving day to avoid any missed bills or important correspondence. They've earned their reputation as Richmond's trusted moving company by consistently delivering on their promise of a stress-free relocation, no matter the distance.

They don't just hire movers; they nurture skilled professionals. Clients can access their belongings with ease, thanks to flexible access hours that cater to busy schedules. Moreover, their adaptability to different moving scenarios is unmatched. Customers can now enjoy a guilt-free moving experience, knowing they're not contributing to the growing problem of landfill waste.

They aren't just a service provider; they're neighbors. BBX Moving excels in local relocations, ensuring a smooth transition from your old home to your new one with unparalleled expertise. They offer comprehensive moving solutions that cover every aspect of the move, from start to finish.

BBX Moving emphasizes the importance of choosing a reputable moving company that specializes in long-distance relocations. BBX Moving's experience in long-haul relocations means they're prepared for these complexities.

It's clear that for those in Richmond and beyond, BBX Moving is the go-to company for local and long-distance moves that exceed expectations. Creating a personal essentials box is another tip from BBX Moving. BBX Moving's software also streamlines the inventory process, ensuring that all items are accounted for. They're equipped to handle moves of any size and distance, whether you're moving across town or across the country.

Their team's meticulous planning and execution mean clients don't have to worry about the details-they're in capable hands. BBX Moving's team is trained to provide timely, empathetic responses, demonstrating their commitment to going above and beyond. Understanding that every move is unique, BBX Moving prioritizes a personalized care approach, ensuring each client's needs are meticulously met.

They're set on making a name for themselves in these new communities, promising the same level of professionalism and care that has made them a trusted name in Richmond. Ensuring the safety of your belongings during a move, BBX Moving offers comprehensive services tailored to meet all your moving needs. While BBX Moving offers comprehensive packing services, they also encourage DIY packing for non-fragile items.

This approach demonstrates their dedication to serving as many clients as possible, making professional moving services accessible to a wider community.

They're equipped with the right tools and materials to ensure that every artwork, whether it's a priceless painting or a delicate sculpture, is packed securely. The founders envisioned a moving service that wouldn't just transport items from point A to B but would do so with unmatched professionalism and care.

Numerous satisfied customers have taken the time to share their positive experiences with BBX Moving, highlighting the company's exceptional service and attention to detail. Recognizing that moving can be a source of stress for many, they've streamlined their guidance to make any transition as seamless as possible. Why does the attire of BBX Moving's team reflect more than just their professional appearance? Their team works closely with clients to understand the nuances of their move, from the amount of packing needed to special care items, ensuring that every aspect is covered.

Furniture refers to objects intended to support various human activities such as seating (e.g., stools, chairs, and sofas), eating (tables), storing items, working, and sleeping (e.g., beds and hammocks). Furniture is also used to hold objects at a convenient height for work (as horizontal surfaces above the ground, such as tables and desks), or to store things (e.g., cupboards, shelves, and drawers). Furniture can be a product of design and can be considered a form of decorative art. In addition to furniture's functional role, it can serve a symbolic or religious purpose. It can be made from a vast multitude of materials, including metal, plastic, and wood. Furniture can be made using a variety of woodworking joints which often reflects the local culture.

People have been using natural objects, such as tree stumps, rocks and moss, as furniture since the beginning of human civilization and continues today in some households/campsites. Archaeological research shows that from around 30,000 years ago, people started to construct and carve their own furniture, using wood, stone, and animal bones. Early furniture from this period is known from artwork such as a Venus figurine found in Russia, depicting the goddess on a throne. The first surviving extant furniture is in the homes of Skara Brae in Scotland, and includes cupboards, dressers and beds all constructed from stone. Complex construction techniques such as joinery began in the early dynastic period of ancient Egypt. This era saw constructed wooden pieces, including stools and tables, sometimes decorated with valuable metals or ivory. The evolution of furniture design continued in ancient Greece and ancient Rome, with thrones being commonplace as well as the klinai, multipurpose couches used for relaxing, eating, and sleeping. The furniture of the Middle Ages was usually heavy, oak, and ornamented. Furniture design expanded during the Italian Renaissance of the fourteenth and fifteenth century. The seventeenth century, in both Southern and Northern Europe, was characterized by opulent, often gilded Baroque designs. The nineteenth century is usually defined by revival styles. The first three-quarters of the twentieth century are often seen as the march towards Modernism. One unique outgrowth of post-modern furniture design is a return to natural shapes and textures.[1]

The English word furniture is derived from the French word fourniture,[2] the noun form of fournir, which means to supply or provide.[3] Thus fourniture in French means supplies or provisions.[4] The English usage, referring specifically to household objects, is specific to that language;[5] French and other Romance languages as well as German use variants of the word meubles, which derives from Latin mobilia, meaning "moveable goods".[6]

The practice of using natural objects as rudimentary pieces of furniture likely dates to the beginning of human civilization.[7] Early humans are likely to have used tree stumps as seats, rocks as rudimentary tables, and mossy areas for sleeping.[7] During the late Paleolithic or early Neolithic period, from around 30,000 years ago, people began constructing and carving their own furniture, using wood, stone and animal bones.[8] The earliest evidence for the existence of constructed furniture is a Venus figurine found at the Gagarino site in Russia, which depicts the goddess in a sitting position, on a throne.[9] A similar statue of a seated woman was found in Çatalhöyük in Turkey, dating to between 6000 and 5500 BCE.[7] The inclusion of such a seat in the figurines implies that these were already common artefacts of that age.[9]

A range of unique stone furniture has been excavated in Skara Brae, a Neolithic village in Orkney, Scotland The site dates from 3100 to 2500 BCE and due to a shortage of wood in Orkney, the people of Skara Brae were forced to build with stone, a readily available material that could be worked easily and turned into items for use within the household. Each house shows a high degree of sophistication and was equipped with an extensive assortment of stone furniture, ranging from cupboards, dressers, and beds to shelves, stone seats, and limpet tanks. The stone dresser was regarded as the most important as it symbolically faces the entrance in each house and is therefore the first item seen when entering, perhaps displaying symbolic objects, including decorative artwork such as several Neolithic carved stone balls also found at the site.

Ancient furniture has been excavated from the 8th-century BCE Phrygian tumulus, the Midas Mound, in Gordion, Turkey. Pieces found here include tables and inlaid serving stands. There are also surviving works from the 9th–8th-century BCE Assyrian palace of Nimrud. The earliest surviving carpet, the Pazyryk Carpet was discovered in a frozen tomb in Siberia and has been dated between the 6th and 3rd century BCE.

Civilization in ancient Egypt began with the clearance and irrigation of land along the banks of the River Nile,[10] which began in about 6000 BCE. By that time, society in the Nile Valley was already engaged in organized agriculture and the construction of large buildings.[11] At this period, Egyptians in the southwestern corner of Egypt were herding cattle and also constructing large buildings. Mortar was in use by around 4000 BCE The inhabitants of the Nile Valley and delta were self-sufficient and were raising barley and emmer (an early variety of wheat) and stored it in pits lined with reed mats.[12] They raised cattle, goats and pigs and they wove linens and baskets.[12] Evidence of furniture from the predynastic period is scarce, but samples from First Dynasty tombs indicate an already advanced use of furnishings in the houses of the age.[13]

During the Dynastic Period, which began in around 3200 BCE, Egyptian art developed significantly, and this included furniture design.[14] Egyptian furniture was primarily constructed using wood, but other materials were sometimes used, such as leather,[15] and pieces were often adorned with gold, silver, ivory and ebony, for decoration.[15] Wood found in Egypt was not suitable for furniture construction, so it had to be imported into the country from other places,[14] particularly Phoenicia.[16] The scarcity of wood necessitated innovation in construction techniques. The use of scarf joints to join two shorter pieces together and form a longer beam was one example of this,[17] as well as construction of veneers in which low quality cheap wood was used as the main building material, with a thin layer of expensive wood on the surface.[18]

The earliest used seating furniture in the dynastic period was the stool, which was used throughout Egyptian society, from the royal family down to ordinary citizens.[19] Various different designs were used, including stools with four vertical legs, and others with crossed splayed legs; almost all had rectangular seats, however.[19] Examples include the workman's stool, a simple three legged structure with a concave seat, designed for comfort during labour,[20] and the much more ornate folding stool, with crossed folding legs,[21] which were decorated with carved duck heads and ivory,[21] and had hinges made of bronze.[19] Full chairs were much rarer in early Egypt, being limited to only wealthy and high ranking people, and seen as a status symbol; they did not reach ordinary households until the 18th dynasty.[22] Early examples were formed by adding a straight back to a stool, while later chairs had an inclined back.[22] Other furniture types in ancient Egypt include tables, which are heavily represented in art, but almost nonexistent as preserved items – perhaps because they were placed outside tombs rather than within,[23] as well as beds and storage chests.[24][25]

Historical knowledge of Greek furniture is derived from various sources, including literature, terracotta, sculptures, statuettes, and painted vases.[26] Some pieces survive to this day, primarily those constructed from metals, including bronze, or marble.[26] Wood was an important and common material in Greek furniture, both domestic and imported.[26] A common technique was to construct the main sections of the furniture with cheap solid wood, then apply a veneer using an expensive wood, such as maple or ebony.[26] Greek furniture construction also made use of dowels and tenons for joining the wooden parts of a piece together.[26] Wood was shaped by carving, steam treatment, and the lathe, and furniture is known to have been decorated with ivory, tortoise shell, glass, gold or other precious materials.[27]

The modern word "throne" is derived from the ancient Greek thronos (Greek singular: θρόνος), which was a seat designated for deities or individuals of high status/hierarchy or honor.[28] The colossal chryselephantine statue of Zeus at Olympia, constructed by Phidias and lost in antiquity, featured the god Zeus seated on an elaborate throne, which was decorated with gold, precious stones, ebony and ivory, according to Pausanias.[29] Other Greek seats included the klismos, an elegant Greek chair with a curved backrest and legs whose form was copied by the Romans and is now part of the vocabulary of furniture design,[30] the backless stool (diphros), which existed in most Greek homes,[31] and folding stool.[32] The kline, used from the late seventh century BCE,[33] was a multipurpose piece used as a bed, but also as a sofa and for reclining during meals.[34] It was rectangular and supported on four legs, two of which could be longer than the other, providing support for an armrest or headboard.[35] Mattresses, rugs, and blankets may have been used, but there is no evidence for sheets.[34]

In general, Greek tables were low and often appear in depictions alongside klinai.[36] The most common type of Greek table had a rectangular top supported on three legs, although numerous configurations exist, including trapezoid and circular.[37] Tables in ancient Greece were used mostly for dining purposes – in depictions of banquets, it appears as though each participant would have used a single table, rather than a collective use of a larger piece.[38] Tables also figured prominently in religious contexts, as indicated in vase paintings, for example, the wine vessel associated with Dionysus, dating to around 450 BCE and now housed at the Art Institute of Chicago.[39] Chests were used for storage of clothes and personal items and were usually rectangular with hinged lids.[37] Chests depicted in terracotta show elaborate patterns and design, including the Greek fret.[34]

Roman furniture was based heavily on Greek furniture, in style and construction. Rome gradually superseded Greece as the foremost culture of Europe, leading eventually to Greece becoming a province of Rome in 146 BC. Rome thus took over production and distribution of Greek furniture, and the boundary between the two is blurred. The Romans did have some limited innovation outside of Greek influence, and styles distinctly their own.[40]

Roman furniture was constructed principally using wood, metal and stone, with marble and limestone used for outside furniture. Very little wooden furniture survives intact, but there is evidence that a variety of woods were used, including maple, citron, beech, oak, and holly. Some imported wood such as satinwood was used for decoration. The most commonly used metal was bronze, of which numerous examples have survived, for example, headrests for couches and metal stools. Similar to the Greeks, Romans used tenons, dowels, nails, and glue to join wooden pieces together, and also practised veneering.[40]

The 1738 and 1748 excavations of Herculaneum and Pompeii revealed Roman furniture, preserved in the ashes of the AD 79 eruption of Vesuvius.

In contrast to the ancient civilizations of Egypt, Greece, and Rome, there is comparatively little evidence of furniture from the 5th to the 15th century.[41] Very few extant pieces survive, and evidence in literature is also scarce.[41] It is likely that the style of furniture prevalent in late antiquity persisted throughout the Middle Ages.[41] For example, a throne similar to that of Zeus is depicted in a sixth-century diptych,[41] while the Bayeux tapestry shows Edward the Confessor and Harold seated on seats similar to the Roman sella curulis.[42] The furniture of the Middle Ages was usually heavy, oak, and ornamented with carved designs.

The Hellenistic influence upon Byzantine furniture can be seen through the use of acanthus leaves, palmettes, bay and olive leaves as ornaments. Oriental influences manifest through rosettes, arabesques and the geometric stylisation of certain vegetal motifs. Christianity brings symbols in Byzantine ornamentation: the pigeon, fishes, the lamb and vines.[43] The furniture from Byzantine houses and palaces was usually luxurious, highly decorated and finely ornamented. Stone, marble, metal, wood and ivory are used. Surfaces and ornaments are gilded, painted plychrome, plated with sheets of gold, emailed in bright colors, and covered in precious stones. The variety of Byzantine furniture is pretty big: tables with square, rectangle or round top, sumptuous decorated, made of wood sometimes inlaid, with bronze, ivory or silver ornaments; chairs with high backs and with wool blankets or animal furs, with coloured pillows, and then banks and stools; wardrobes were used only for storing books; cloths and valuable objects were kept in chests, with iron locks; the form of beds imitated the Roman ones, but have different designs of legs.[44]

The main ornament of Gothic furniture and all applied arts is the ogive. The geometric rosette accompanies the ogive many times, having a big variety of forms. Architectural elements are used at furniture, at the beginning with purely decorative reasons, but later as structure elements. Besides the ogive, the main ornaments are: acanthus leaves, ivy, oak leaves, haulms, clovers, fleurs-de-lis, knights with shields, heads with crowns and characters from the Bible. Chests are the main type of Gothic furniture used by the majority of the population. Usually, the locks and escutcheon of chests have also an ornamental scope, being finely made.[45]

Along with the other arts, the Italian Renaissance of the fourteenth and fifteenth century marked a rebirth in design, often inspired by the Greco-Roman tradition. A similar explosion of design, and renaissance of culture in general occurred in Northern Europe, starting in the fifteenth century.

The 17th century, in both Southern and Northern Europe, was characterized by opulent, often gilded Baroque designs that frequently incorporated a profusion of vegetal and scrolling ornament. Starting in the eighteenth century, furniture designs began to develop more rapidly. Although there were some styles that belonged primarily to one nation, such as Palladianism in Great Britain or Louis Quinze in French furniture, others, such as the Rococo and Neoclassicism were perpetuated throughout Western Europe.

During the 18th century, the fashion was set in England by the French art. In the beginning of the century Boulle cabinets were at the peak of their popularity and Louis XIV was reigning in France. In this era, most of the furniture had metal and enamelled decorations in it and some of the furniture was covered in inlays of marbles lapis lazuli, and porphyry and other stones. By mid-century this Baroque style was displaced by the graceful curves, shining ormolu, and intricate marquetry of the Rococo style, which in turn gave way around 1770 to the more severe lines of Neoclassicism, modeled after the architecture of ancient Greece and Rome.[52] Creating a mass market for furniture, the distinguished London cabinet maker Thomas Chippendale's The Gentleman and Cabinet Maker's Director (1754) is regarded as the "first comprehensive trade catalogue of its kind".[53]

There is something so distinct in the development of taste in French furniture, marked out by the three styles to which the three monarchs have given the name of "Louis Quatorze", "Louis Quinze", and "Louis Seize". This will be evident to anyone who will visit, first the Palace of Versailles, then the Grand Trianon, and afterwards the Petit Trianon.[54]

The nineteenth century is usually defined by concurrent revival styles, including Gothic, Neoclassicism, and Rococo. The design reforms of the late century introduced the Aesthetic movement and the Arts and Crafts movement. Art Nouveau was influenced by both of these movements. Shaker-style furniture became popular during this time in North America as well.

This design was in many ways rooted in necessity and emphasizes both form and materials. Early British Colonial American[vague] chairs and tables are often constructed with turned spindles and chair backs often constructed with steaming to bend the wood. Wood choices tend to be deciduous hardwoods with a particular emphasis on the wood of edible or fruit bearing trees such as cherry or walnut.[citation needed]

This section needs expansion. You can help by adding to it. (January 2023) |

The first three-quarters of the 20th century is seen as the march towards Modernism. The furniture designers of Art Deco, De Stijl, Bauhaus, Jugendstil, Wiener Werkstätte, and Vienna Secession all worked to some degree within the Modernist motto.

Born from the Bauhaus and Streamline Moderne came the post-World War II style "Mid-Century Modern". Mid-Century Modern materials developed during the war including laminated plywood, plastics, and fiberglass. Prime examples include furniture designed by George Nelson Associates, Charles and Ray Eames, Paul McCobb, Florence Knoll, Harry Bertoia, Eero Saarinen, Harvey Probber, Vladimir Kagan and Danish modern designers including Finn Juhl and Arne Jacobsen.

Postmodern design, intersecting the Pop art movement, gained steam in the 1960s and 70s, promoted in the 80s by groups such as the Italy-based Memphis movement. Transitional furniture is intended to fill a place between Traditional and Modern tastes.[citation needed]

Great efforts from individuals, governments, and companies has led to the manufacturing of products with higher sustainability known as Ecodesign. This new line of furniture is based on environmentally friendly design. Its use and popularity are increasing each year.[69]

Industrialisation, Post-Modernism, and the Internet have allowed furniture design to become more accessible to a wider range of people than ever before. There are many modern styles of furniture design, each with roots in Classical, Modernist, and Post-Modern design and art movements. The growth of Maker Culture across the Western sphere of influence has encouraged higher participation and development of new, more accessible furniture design techniques. One unique outgrowth of this post-modern furniture design trajectory is Live Edge, which incorporates the natural surface of a tree as part of a furniture object, heralding a resurgence of these natural shapes and textures within the home.[1] Additionally, the use of Epoxy Resin has become more prevalent in DIY furniture styles.

Asian furniture has a quite distinct history. The traditions out of India, China, Korea, Pakistan, Indonesia (Bali and Java) and Japan are some of the best known, but places such as Mongolia, and the countries of South East Asia have unique facets of their own.

The use of uncarved wood and bamboo and the use of heavy lacquers are well known Chinese styles. It is worth noting that Chinese furniture varies dramatically from one dynasty to the next. Chinese ornamentation is highly inspired by paintings, with floral and plant life motifs including bamboo trees, chrysanthemums, waterlilies, irises, magnolias, flowers and branches of cherry, apple, apricot and plum, or elongated bamboo leaves; animal ornaments include lions, bulls, ducks, peacocks, parrots, pheasants, roosters, ibises and butterflies. The dragon is the symbol of earth fertility, and of the power and wisdom of the emperor. Lacquers are mostly populated with princesses, various Chinese people, soldiers, children, ritually and daily scenes. Architectural features tend toward geometric ornaments, like meanders and labyrinths. The interior of a Chinese house was simple and sober. All Chinese furniture is made of wood, usually ebony, teak, or rosewood for heavier furniture (chairs, tables and benches) and bamboo, pine and larch for lighter furniture (stools and small chairs).[70]

Traditional Japanese furniture is well known for its minimalist style, extensive use of wood, high-quality craftsmanship and reliance on wood grain instead of painting or thick lacquer. Japanese chests are known as Tansu, known for elaborate decorative iron work, and are some of the most sought-after of Japanese antiques. The antiques available generally date back to the Tokugawa and Meiji periods. Both the technique of lacquering and the specific lacquer (resin of Rhus vernicifera) originated in China, but the lacquer tree also grows well in Japan. The recipes of preparation are original to Japan: resin is mixed with wheat flour, clay or pottery powder, turpentine, iron powder or wood coal. In ornamentation, the chrysanthemum, known as kiku, the national flower, is a very popular ornament, including the 16-petal chrysanthemum symbolizing the Emperor. Cherry and apple flowers are used for decorating screens, vases and shōji. Common animal ornaments include dragons, carps, cranes, gooses, tigers, horses and monkeys; representations of architecture such as houses, pavilions, towers, torii gates, bridges and temples are also common. The furniture of a Japanese house consists of tables, shelves, wardrobes, small holders for flowers, bonsais or for bonkei, boxes, lanterns with wooden frames and translucent paper, neck and elbow holders, and jardinieres.[71]

Seating is amongst the oldest known furniture types, and authors including Encyclopædia Britannica regard it as the most important.[2] In addition to the functional design, seating has had an important decorative element from ancient times to the present day. This includes carved and sculpted pieces intended as works of art, as well as the styling of seats to indicate social importance, with senior figures or leaders granted the use of specially designed seats.[2]

The simplest form of seat is the chair,[72] which is a piece of furniture designed to allow a single person to sit down, which has a back and legs, as well as a platform for sitting.[73] Chairs often feature cushions made from various fabrics.[74]

All different types of woods have unique signature marks that can help in easy identification of the type. Hardwood and softwood are the two main categories for wood. Both hardwoods and softwoods are used in furniture manufacturing, and each has its own specific uses. Deciduous trees, which have broad leaves that change color periodically throughout the year, are the source of hardwood. Coniferous trees, also known as cone-bearing trees, have small leaves or needles that stay on the tree throughout the year.[75][76] Common softwoods used include pine, redwood and yew. Higher quality furniture tends to be made out of hardwood, including oak, maple, mahogany, teak, walnut, cherry and birch. Highest quality wood will have been air dried to rid it of its moisture.[77]

A popular furniture hardwood is American black cherry. Cherry is a light reddish brown to brown color that intensifies into a rich color as it ages, and grows mostly in the eastern United States. Cherry has a tighter grain than birch and is softer. Much cherry lumber is narrow, and it has been utilized to make many lovely classic furniture pieces.[75]

Birch is a sturdy, durable, even-textured hardwood that is common in the United States and Canada. The wood appears white or creamy yellow to light brown with a crimson tinge in its natural state. Birch is frequently stained to complement other types of wood in furniture. Birch is used to make a lot of transparent, cabinet-grade plywood because it absorbs stain well and finishes beautifully. Birch is frequently used to construct interior doors and cupboards in addition to furniture.[75]

Restoring a piece of furniture may imply attempting to repair and revive the original finish in some way. More often than not, this entails removing the existing treatment and preparing the raw wood for a new finish. Methods for repair depend on what kind of wood it is: solid or veneered, hardwood or softwood, open grained or closed grained. These variables can sometimes decide if a piece of furniture is worth repairing, as well as the type of repairs and finish it will require if it is restored. The 3 methods of restoring furniture are rejuvenate, repair, and refinish.

Rejuvenate The piece can easily be restored by just cleaning and waxing the surface while preserving the current finish. It works on wooden furniture that is still in good shape and is the simplest way to clean it.

Repair This process can fix dents and cracks by touching up some worn-out areas without removing the surface with this technique, the finish can be maintained while repairing the object with specialized products.

Refinish Remove anything that is left for example any paint with a finish-stripper product or lightly sanding the area down and then applying wood finish like oil wax in order to protect the secure the wood.[75]

Cleaning Remove dirt, dust, and grime from the furniture using a mild soap or specialized furniture cleaner.

The examples and perspective in this section may not represent a worldwide view of the subject. (October 2018) |

Recycling is the process of converting waste materials into new materials and objects. This concept often includes the recovery of energy from waste materials. The recyclability of a material depends on its ability to reacquire the properties it had in its original state.[1] It is an alternative to "conventional" waste disposal that can save material and help lower greenhouse gas emissions. It can also prevent the waste of potentially useful materials and reduce the consumption of fresh raw materials, reducing energy use, air pollution (from incineration) and water pollution (from landfilling).

Recycling is a key component of modern waste reduction and is the third component of the "Reduce, Reuse, and Recycle" waste hierarchy.[2][3] It promotes environmental sustainability by removing raw material input and redirecting waste output in the economic system.[4] There are some ISO standards related to recycling, such as ISO 15270:2008 for plastics waste and ISO 14001:2015 for environmental management control of recycling practice.

Recyclable materials include many kinds of glass, paper, cardboard, metal, plastic, tires, textiles, batteries, and electronics. The composting and other reuse of biodegradable waste—such as food and garden waste—is also a form of recycling.[5] Materials for recycling are either delivered to a household recycling center or picked up from curbside bins, then sorted, cleaned, and reprocessed into new materials for manufacturing new products.

In ideal implementations, recycling a material produces a fresh supply of the same material—for example, used office paper would be converted into new office paper, and used polystyrene foam into new polystyrene. Some types of materials, such as metal cans, can be remanufactured repeatedly without losing their purity.[6] With other materials, this is often difficult or too expensive (compared with producing the same product from raw materials or other sources), so "recycling" of many products and materials involves their reuse in producing different materials (for example, paperboard). Another form of recycling is the salvage of constituent materials from complex products, due to either their intrinsic value (such as lead from car batteries and gold from printed circuit boards), or their hazardous nature (e.g. removal and reuse of mercury from thermometers and thermostats).

Reusing materials has been a common practice for most of human history with recorded advocates as far back as Plato in the fourth century BC.[7] During periods when resources were scarce, archaeological studies of ancient waste dumps show less household waste (such as ash, broken tools, and pottery), implying that more waste was recycled in place of new material.[8] However, archaeological artefacts made from recyclable material, such as glass or metal, may neither be the original object nor resemble it, with the consequence that a successful ancient recycling economy can become invisible when recycling is synonymous with re-melting rather than reuse.[9]

In pre-industrial times, there is evidence of scrap bronze and other metals being collected in Europe and melted down for continuous reuse.[10] Paper recycling was first recorded in 1031 when Japanese shops sold repulped paper.[11][12] In Britain dust and ash from wood and coal fires was collected by "dustmen" and downcycled as a base material for brick making. These forms of recycling were driven by the economic advantage of obtaining recycled materials instead of virgin material, and the need for waste removal in ever-more-densely populated areas.[8] In 1813, Benjamin Law developed the process of turning rags into "shoddy" and "mungo" wool in Batley, Yorkshire, which combined recycled fibers with virgin wool.[13] The West Yorkshire shoddy industry in towns such as Batley and Dewsbury lasted from the early 19th century to at least 1914.

Industrialization spurred demand for affordable materials. In addition to rags, ferrous scrap metals were coveted as they were cheaper to acquire than virgin ore. Railroads purchased and sold scrap metal in the 19th century, and the growing steel and automobile industries purchased scrap in the early 20th century. Many secondary goods were collected, processed and sold by peddlers who scoured dumps and city streets for discarded machinery, pots, pans, and other sources of metal. By World War I, thousands of such peddlers roamed the streets of American cities, taking advantage of market forces to recycle post-consumer materials into industrial production.[14]

Manufacturers of beverage bottles, including Schweppes,[15] began offering refundable recycling deposits in Great Britain and Ireland around 1800. An official recycling system with refundable deposits for bottles was established in Sweden in 1884, and for aluminum beverage cans in 1982; it led to recycling rates of 84–99%, depending on type (glass bottles can be refilled around 20 times).[16]

New chemical industries created in the late 19th century both invented new materials (e.g. Bakelite in 1907) and promised to transform valueless into valuable materials. Proverbially, you could not make a silk purse of a sow's ear—until the US firm Arthur D. Little published in 1921 "On the Making of Silk Purses from Sows' Ears", its research proving that when "chemistry puts on overalls and gets down to business [...] new values appear. New and better paths are opened to reach the goals desired."[17]

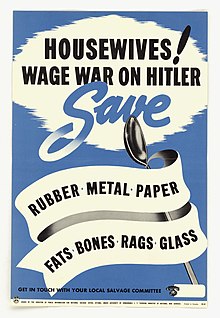

Recycling—or "salvage", as it was then usually known—was a major issue for governments during World War II, where financial constraints and significant material shortages made it necessary to reuse goods and recycle materials.[18] These resource shortages caused by the world wars, and other such world-changing events, greatly encouraged recycling.[19][18] It became necessary for most homes to recycle their waste, allowing people to make the most of what was available. Recycling household materials also meant more resources were left available for war efforts.[18] Massive government campaigns, such as the National Salvage Campaign in Britain and the Salvage for Victory campaign in the United States, occurred in every fighting nation, urging citizens to donate metal, paper, rags, and rubber as a patriotic duty.

A considerable investment in recycling occurred in the 1970s due to rising energy costs.[20] Recycling aluminium uses only 5% of the energy of virgin production. Glass, paper and other metals have less dramatic but significant energy savings when recycled.[21]

Although consumer electronics have been popular since the 1920s, recycling them was almost unheard of until early 1991.[22] The first electronic waste recycling scheme was implemented in Switzerland, beginning with collection of old refrigerators, then expanding to cover all devices.[23] When these programs were created, many countries could not deal with the sheer quantity of e-waste, or its hazardous nature, and began to export the problem to developing countries without enforced environmental legislation. (For example, recycling computer monitors in the United States costs 10 times more than in China.) Demand for electronic waste in Asia began to grow when scrapyards found they could extract valuable substances such as copper, silver, iron, silicon, nickel, and gold during the recycling process.[24] The 2000s saw a boom in both the sales of electronic devices and their growth as a waste stream: In 2002, e-waste grew faster than any other type of waste in the EU.[25] This spurred investment in modern automated facilities to cope with the influx, especially after strict laws were implemented in 2003.[26]

As of 2014, the European Union had about 50% of world share of waste and recycling industries, with over 60,000 companies employing 500,000 people and a turnover of €24 billion.[27] EU countries are mandated to reach recycling rates of at least 50%; leading countries are already at around 65%. The overall EU average was 39% in 2013[28] and is rising steadily, to 45% in 2015.[29][30]

In 2015, the United Nations General Assembly set 17 Sustainable Development Goals. Goal 12, Responsible Consumption and Production, specifies 11 targets "to ensure sustainable consumption and production patterns".[31] The fifth target, Target 12.5, is defined as substantially reducing waste generation by 2030, indicated by the National Recycling Rate.

In 2018, changes in the recycling industry have sparked a global "crisis". On 31 December 2017, China announced its "National Sword" policy, setting new standards for imports of recyclable material and banning materials deemed too "dirty" or "hazardous". The new policy caused drastic disruptions in the global recycling market, and reduced the prices of scrap plastic and low-grade paper. Exports of recyclable materials from G7 countries to China dropped dramatically, with many shifting to countries in southeast Asia. This generated significant concern about the recycling industry's practices and environmental sustainability. The abrupt shift caused countries to accept more materials than they could process, and raised fundamental questions about shipping waste from developed countries to countries with few environmental regulations—a practice that predated the crisis.[32]

This section needs expansion. You can help by adding to it. Find sources: "recycling health" – news · newspapers · books · scholar · JSTOR (December 2023) |

According to the WHO (2023), “Every year millions of electrical and electronic devices are discarded ... a threat to the environment and to human health if they are not treated, disposed of, and recycled appropriately. Common items ... include computers ... e-waste are recycled using environmentally unsound techniques and are likely stored in homes and warehouses, dumped, exported or recycled under inferior conditions. When e-waste is treated using inferior activities, it can release as many as 1000 different chemical substances ... including harmful neurotoxicants such as lead.”[33] A paper in the journal Sustainable Materials & Technologies remarks upon the difficulty of managing e-waste, particularly from home automation products, which, due to their becoming obsolete at a high rate, are putting increasing strain on recycling systems, which have not adapted to meet the recycling needs posed by this type of product.[34]

Copper slag is obtained when copper and nickel ores are recovered from their source ores using a pyrometallurgical process, and these ores usually contain other elements which include iron, cobalt, silica, and alumina.[35] An estimate of 2.2–3 tons of copper slag is generated per ton of copper produced, resulting in around 24.6 tons of slag per year, which is regarded as waste.[36] [37]

Environmental impact of slag include copper paralysis, which leads to death due to gastric hemorrhage, if ingested by humans. It may also cause acute dermatitis upon skin exposure. [38] Toxicity may also be uptaken by crops through soil, consequently spreading animals and food sources and increasing the risk of cardiovascular diseases, cancer, cognitive impairment, chronic anemia, and damage to kidneys, bones, nervous system, brain and skin.[39]

Substituting gravel and grit in quarries has been more cost-effective, due to having its sources with better proximity to consumer markets. Trading between countries and establishment of blast furnaces is helping increase slag utilization, hence reducing wastage and pollution.[40]

This section is empty. You can help by adding to it. Find sources: "Concrete recycling health" – news · newspapers · books · scholar · JSTOR (December 2023) |

Economist Steven Landsburg, author of a paper entitled "Why I Am Not an Environmentalist",[41] claimed that paper recycling actually reduces tree populations. He argues that because paper companies have incentives to replenish their forests, large demands for paper lead to large forests while reduced demand for paper leads to fewer "farmed" forests.[42]

When foresting companies cut down trees, more are planted in their place; however, such farmed forests are inferior to natural forests in several ways. Farmed forests are not able to fix the soil as quickly as natural forests. This can cause widespread soil erosion and often requiring large amounts of fertilizer to maintain the soil, while containing little tree and wild-life biodiversity compared to virgin forests.[43] Also, the new trees planted are not as big as the trees that were cut down, and the argument that there would be "more trees" is not compelling to forestry advocates when they are counting saplings.

In particular, wood from tropical rainforests is rarely harvested for paper because of their heterogeneity.[44] According to the United Nations Framework Convention on Climate Change secretariat, the overwhelming direct cause of deforestation is subsistence farming (48% of deforestation) and commercial agriculture (32%), which is linked to food, not paper production.[45]

Other non-conventional methods of material recycling, like Waste-to-Energy (WTE) systems, have garnered increased attention in the recent past due to the polarizing nature of their emissions. While viewed as a sustainable method of capturing energy from material waste feedstocks by many, others have cited numerous explanations for why the technology has not been scaled globally.[46]

For a recycling program to work, a large, stable supply of recyclable material is crucial. Three legislative options have been used to create such supplies: mandatory recycling collection, container deposit legislation, and refuse bans. Mandatory collection laws set recycling targets for cities, usually in the form that a certain percentage of a material must be diverted from the city's waste stream by a target date. The city is responsible for working to meet this target.[5]

Container deposit legislation mandates refunds for the return of certain containers—typically glass, plastic and metal. When a product in such a container is purchased, a small surcharge is added that the consumer can reclaim when the container is returned to a collection point. These programs have succeeded in creating an average 80% recycling rate.[47] Despite such good results, the shift in collection costs from local government to industry and consumers has created strong opposition in some areas[5]—for example, where manufacturers bear the responsibility for recycling their products. In the European Union, the WEEE Directive requires producers of consumer electronics to reimburse the recyclers' costs.[48]

An alternative way to increase the supply of recyclates is to ban the disposal of certain materials as waste, often including used oil, old batteries, tires, and garden waste. This can create a viable economy for the proper disposal of the products. Care must be taken that enough recycling services exist to meet the supply, or such bans can create increased illegal dumping.[5]

Four forms of legislation have also been used to increase and maintain the demand for recycled materials: minimum recycled content mandates, utilization rates, procurement policies, and recycled product labeling.[5]

Both minimum recycled content mandates and utilization rates increase demand by forcing manufacturers to include recycling in their operations. Content mandates specify that a certain percentage of a new product must consist of recycled material. Utilization rates are a more flexible option: Industries can meet their recycling targets at any point of their operations, or even contract out recycling in exchange for tradable credits. Opponents to these methods cite their large increase in reporting requirements, and claim that they rob the industry of flexibility.[5][49]

Governments have used their own purchasing power to increase recycling demand through "procurement policies". These policies are either "set-asides", which reserve a certain amount of spending for recycled products; or "price preference" programs that provide larger budgets when recycled items are purchased. Additional regulations can target specific cases: in the United States, for example, the Environmental Protection Agency mandates the purchase of oil, paper, tires and building insulation from recycled or re-refined sources whenever possible.[5]

The final government regulation toward increased demand is recycled product labeling. When producers are required to label their packaging with the amount of recycled material it contains (including the packaging), consumers can make more educated choices. Consumers with sufficient buying power can choose more environmentally conscious options, prompting producers to increase the recycled material in their products and increase demand. Standardized recycling labeling can also have a positive effect on the supply of recyclates when it specifies how and where the product can be recycled.[5]

"Recyclate" is a raw material sent to and processed in a waste recycling plant or materials-recovery facility[50] so it can be used in the production of new materials and products. For example, plastic bottles can be made into plastic pellets and synthetic fabrics.[51]

The quality of recyclates is one of the principal challenges for the success of a long-term vision of a green economy and achieving zero waste. It generally refers to how much of it is composed of target material, versus non-target material and other non-recyclable material.[52] Steel and other metals have intrinsically higher recyclate quality; it is estimated that two-thirds of all new steel comes from recycled steel.[53] Only target material is likely to be recycled, so higher amounts of non-target and non-recyclable materials can reduce the quantity of recycled products.[52] A high proportion of non-target and non-recyclable material can make it more difficult to achieve "high-quality" recycling; and if recyclate is of poor quality, it is more likely to end up being down-cycled or, in more extreme cases, sent to other recovery options or landfilled.[52] For example, to facilitate the remanufacturing of clear glass products, there are tight restrictions for colored glass entering the re-melt process. Another example is the downcycling of plastic, where products such as plastic food packaging are often downcycled into lower quality products, and do not get recycled into the same plastic food packaging.

The quality of recyclate not only supports high-quality recycling, but it can also deliver significant environmental benefits by reducing, reusing, and keeping products out of landfills.[52] High-quality recycling can support economic growth by maximizing the value of waste material.[52] Higher income levels from the sale of quality recyclates can return value significant to local governments, households and businesses.[52] Pursuing high-quality recycling can also promote consumer and business confidence in the waste and resource management sector, and may encourage investment in it.

There are many actions along the recycling supply chain, each of which can affect recyclate quality.[54] Waste producers who place non-target and non-recyclable wastes in recycling collections can affect the quality of final recyclate streams, and require extra efforts to discard those materials at later stages in the recycling process.[54] Different collection systems can induce different levels of contamination. When multiple materials are collected together, extra effort is required to sort them into separate streams and can significantly reduce the quality of the final products.[54] Transportation and the compaction of materials can also make this more difficult. Despite improvements in technology and quality of recyclate, sorting facilities are still not 100% effective in separating materials.[54] When materials are stored outside, where they can become wet, can also cause problems for re-processors. Further sorting steps may be required to satisfactorily reduce the amount of non-target and non-recyclable material.[54]

A number of systems have been implemented to collect recyclates from the general waste stream, occupying different places on the spectrum of trade-off between public convenience and government ease and expense. The three main categories of collection are drop-off centers, buy-back centers and curbside collection.[5] About two-thirds of the cost of recycling is incurred in the collection phase.[55]

Curbside collection encompasses many subtly different systems, which differ mostly on where in the process the recyclates are sorted and cleaned. The main categories are mixed waste collection, commingled recyclables, and source separation.[5] A waste collection vehicle generally picks up the waste.

In mixed waste collection, recyclates are collected mixed with the rest of the waste, and the desired materials are sorted out and cleaned at a central sorting facility. This results in a large amount of recyclable waste (especially paper) being too soiled to reprocess, but has advantages as well: The city need not pay for the separate collection of recyclates, no public education is needed, and any changes to the recyclability of certain materials are implemented where sorting occurs.[5]

In a commingled or single-stream system, recyclables are mixed but kept separate from non-recyclable waste. This greatly reduces the need for post-collection cleaning, but requires public education on what materials are recyclable.[5][10]

Source separation is the other extreme, where each material is cleaned and sorted prior to collection. It requires the least post-collection sorting and produces the purest recyclates. However, it incurs additional operating costs for collecting each material, and requires extensive public education to avoid recyclate contamination.[5] In Oregon, USA, Oregon DEQ surveyed multi-family property managers; about half of them reported problems, including contamination of recyclables due to trespassers such as transients gaining access to collection areas.[56]

Source separation used to be the preferred method due to the high cost of sorting commingled (mixed waste) collection. However, advances in sorting technology have substantially lowered this overhead, and many areas that had developed source separation programs have switched to what is called co-mingled collection.[10]

At buy-back centers, separated, cleaned recyclates are purchased, providing a clear incentive for use and creating a stable supply. The post-processed material can then be sold. If profitable, this conserves the emission of greenhouse gases; if unprofitable, it increases their emission. Buy-back centres generally need government subsidies to be viable. According to a 1993 report by the U.S. National Waste & Recycling Association, it costs an average $50 to process a ton of material that can be resold for $30.[5]

Drop-off centers require the waste producer to carry recyclates to a central location—either an installed or mobile collection station or the reprocessing plant itself. They are the easiest type of collection to establish but suffer from low and unpredictable throughput.

For some waste materials such as plastic, recent technical devices called recyclebots[57] enable a form of distributed recycling called DRAM (distributed recycling additive manufacturing). Preliminary life-cycle analysis (LCA) indicates that such distributed recycling of HDPE to make filament for 3D printers in rural regions consumes less energy than using virgin resin, or using conventional recycling processes with their associated transportation.[58][59]

Another form of distributed recycling mixes waste plastic with sand to make bricks in Africa.[60] Several studies have looked at the properties of recycled waste plastic and sand bricks.[61][62] The composite pavers can be sold at 100% profit while employing workers at 1.5× the minimum wage in the West African region, where distributed recycling has the potential to produce 19 million pavement tiles from 28,000 tons of plastic water sachets annually in Ghana, Nigeria, and Liberia.[63] This has also been done with COVID19 masks.[64]

Once commingled recyclates are collected and delivered to a materials recovery facility, the materials must be sorted. This is done in a series of stages, many of which involve automated processes, enabling a truckload of material to be fully sorted in less than an hour.[10] Some plants can now sort materials automatically; this is known as single-stream recycling. Automatic sorting may be aided by robotics and machine learning.[65][66] In plants, a variety of materials is sorted including paper, different types of plastics, glass, metals, food scraps, and most types of batteries.[67] A 30% increase in recycling rates has been seen in areas with these plants.[68] In the US, there are over 300 materials recovery facilities.[69]

Initially, commingled recyclates are removed from the collection vehicle and placed on a conveyor belt spread out in a single layer. Large pieces of corrugated fiberboard and plastic bags are removed by hand at this stage, as they can cause later machinery to jam.[10]

Next, automated machinery such as disk screens and air classifiers separate the recyclates by weight, splitting lighter paper and plastic from heavier glass and metal. Cardboard is removed from mixed paper, and the most common types of plastic—PET (#1) and HDPE (#2)—are collected, so these materials can be diverted into the proper collection channels. This is usually done by hand; but in some sorting centers, spectroscopic scanners are used to differentiate between types of paper and plastic based on their absorbed wavelengths.[10] Plastics tend to be incompatible with each other due to differences in chemical composition; their polymer molecules repel each other, similar to oil and water.[70]

Strong magnets are used to separate out ferrous metals such as iron, steel and tin cans. Non-ferrous metals are ejected by magnetic eddy currents: A rotating magnetic field induces an electric current around aluminum cans, creating an eddy current inside the cans that is repulsed by a large magnetic field, ejecting the cans from the stream.[10]

Finally, glass is sorted according to its color: brown, amber, green, or clear. It may be sorted either by hand,[10] or by a machine that uses colored filters to detect colors. Glass fragments smaller than 10 millimetres (0.39 in) cannot be sorted automatically, and are mixed together as "glass fines".[71]

In 2003, San Francisco's Department of the Environment set a citywide goal of zero waste by 2020.[72] San Francisco's refuse hauler, Recology, operates an effective recyclables sorting facility that has helped the city reach a record-breaking landfill diversion rate of 80% as of 2021.[73] Other American cities, including Los Angeles, have achieved similar rates.

Although many government programs concentrate on recycling at home, 64% of waste in the United Kingdom is generated by industry.[74] The focus of many recycling programs in industry is their cost-effectiveness. The ubiquitous nature of cardboard packaging makes cardboard a common waste product recycled by companies that deal heavily in packaged goods, such as retail stores, warehouses, and goods distributors. Other industries deal in niche and specialized products, depending on the waste materials they handle.

Glass, lumber, wood pulp and paper manufacturers all deal directly in commonly recycled materials; however, independent tire dealers may collect and recycle rubber tires for a profit.

The waste produced from burning coal in a Coal-fired power station is often called fuel ash or fly ash in the United States. It is a very useful material and used in concrete construction. It exhibits Pozzolanic activity.[75]

Levels of metals recycling are generally low. In 2010, the International Resource Panel, hosted by the United Nations Environment Programme (UNEP), published reports on metal stocks[76] and their recycling rates.[76] It reported that the increase in the use of metals during the 20th and into the 21st century has led to a substantial shift in metal stocks from below-ground to use in above-ground applications within society. For example, in the US, in-use copper grew from 73 to 238 kg per capita between 1932–1999.

The report's authors observed that, as metals are inherently recyclable, metal stocks in society can serve as huge above-ground mines (the term "urban mining" has thus been coined[77]). However, they found that the recycling rates of many metals are low. They warned that the recycling rates of some rare metals used in applications such as mobile phones, battery packs for hybrid cars and fuel cells, are so low that unless future end-of-life recycling rates are dramatically increased, these critical metals will become unavailable for use in modern technology.

The military recycles some metals. The U.S. Navy's Ship Disposal Program uses ship breaking to reclaim the steel of old vessels. Ships may also be sunk to create artificial reefs. Uranium is a dense metal that has qualities superior to lead and titanium for many military and industrial uses. Uranium left over from processing it into nuclear weapons and fuel for nuclear reactors is called depleted uranium, and is used by all branches of the U.S. military for the development of such things as armor-piercing shells and shielding.

The construction industry may recycle concrete and old road surface pavement, selling these materials for profit.

Some rapidly growing industries, particularly the renewable energy and solar photovoltaic technology industries, are proactively creating recycling policies even before their waste streams have considerable volume, anticipating future demand.[78]

Recycling of plastics is more difficult, as most programs are not able to reach the necessary level of quality. Recycling of PVC often results in downcycling of the material, which means only products of lower quality standard can be made with the recycled material.

E-waste is a growing problem, accounting for 20–50 million metric tons of global waste per year according to the EPA. It is also the fastest growing waste stream in the EU.[25] Many recyclers do not recycle e-waste responsibly. After the cargo barge Khian Sea dumped 14,000 metric tons of toxic ash in Haiti, the Basel Convention was formed to stem the flow of hazardous substances into poorer countries. They created the e-Stewards certification to ensure that recyclers are held to the highest standards for environmental responsibility and to help consumers identify responsible recyclers. It operates alongside other prominent legislation, such as the Waste Electrical and Electronic Equipment Directive of the EU and the United States National Computer Recycling Act, to prevent poisonous chemicals from entering waterways and the atmosphere.

In the recycling process, television sets, monitors, cell phones, and computers are typically tested for reuse and repaired. If broken, they may be disassembled for parts still having high value if labor is cheap enough. Other e-waste is shredded to pieces roughly 10 centimetres (3.9 in) in size and manually checked to separate toxic batteries and capacitors, which contain poisonous metals. The remaining pieces are further shredded to 10 millimetres (0.39 in) particles and passed under a magnet to remove ferrous metals. An eddy current ejects non-ferrous metals, which are sorted by density either by a centrifuge or vibrating plates. Precious metals can be dissolved in acid, sorted, and smelted into ingots. The remaining glass and plastic fractions are separated by density and sold to re-processors. Television sets and monitors must be manually disassembled to remove lead from CRTs and the mercury backlight from LCDs.[79][80][81]

Vehicles, solar panels and wind turbines can also be recycled. They often contain rare-earth elements (REE) and/or other critical raw materials. For electric car production, large amounts of REE's are typically required.[82]

Whereas many critical raw elements and REE's can be recovered, environmental engineer Phillipe Bihouix Archived 6 September 2021 at the Wayback Machine reports that recycling of indium, gallium, germanium, selenium, and tantalum is still very difficult and their recycling rates are very low.[82]

Plastic recycling is the process of recovering scrap or waste plastic and reprocessing the material into useful products, sometimes completely different in form from their original state. For instance, this could mean melting down soft drink bottles and then casting them as plastic chairs and tables.[83] For some types of plastic, the same piece of plastic can only be recycled about 2–3 times before its quality decreases to the point where it can no longer be used.[6]

Some plastics are remelted to form new plastic objects; for example, PET water bottles can be converted into polyester destined for clothing. A disadvantage of this type of recycling is that the molecular weight of the polymer can change further and the levels of unwanted substances in the plastic can increase with each remelt.[84][85]

A commercial-built recycling facility was sent to the International Space Station in late 2019. The facility takes in plastic waste and unneeded plastic parts and physically converts them into spools of feedstock for the space station additive manufacturing facility used for in-space 3D printing.[86]

For some polymers, it is possible to convert them back into monomers, for example, PET can be treated with an alcohol and a catalyst to form a dialkyl terephthalate. The terephthalate diester can be used with ethylene glycol to form a new polyester polymer, thus making it possible to use the pure polymer again. In 2019, Eastman Chemical Company announced initiatives of methanolysis and syngas designed to handle a greater variety of used material.[87]

Another process involves the conversion of assorted polymers into petroleum by a much less precise thermal depolymerization process. Such a process would be able to accept almost any polymer or mix of polymers, including thermoset materials such as vulcanized rubber tires and the biopolymers in feathers and other agricultural waste. Like natural petroleum, the chemicals produced can be used as fuels or as feedstock. A RESEM Technology[88] plant of this type in Carthage, Missouri, US, uses turkey waste as input material. Gasification is a similar process but is not technically recycling since polymers are not likely to become the result. Plastic Pyrolysis can convert petroleum based waste streams such as plastics into quality fuels, carbons. Given below is the list of suitable plastic raw materials for pyrolysis:

In order to meet recyclers' needs while providing manufacturers a consistent, uniform system, a coding system was developed. The recycling code for plastics was introduced in 1988 by the plastics industry through the Society of the Plastics Industry.[89] Because municipal recycling programs traditionally have targeted packaging—primarily bottles and containers—the resin coding system offered a means of identifying the resin content of bottles and containers commonly found in the residential waste stream.[90]

In the United States, plastic products are printed with numbers 1–7 depending on the type of resin. Type 1 (polyethylene terephthalate) is commonly found in soft drink and water bottles. Type 2 (high-density polyethylene) is found in most hard plastics such as milk jugs, laundry detergent bottles, and some dishware. Type 3 (polyvinyl chloride) includes items such as shampoo bottles, shower curtains, hula hoops, credit cards, wire jacketing, medical equipment, siding, and piping. Type 4 (low-density polyethylene) is found in shopping bags, squeezable bottles, tote bags, clothing, furniture, and carpet. Type 5 is polypropylene and makes up syrup bottles, straws, Tupperware, and some automotive parts. Type 6 is polystyrene and makes up meat trays, egg cartons, clamshell containers, and compact disc cases. Type 7 includes all other plastics such as bulletproof materials, 3- and 5-gallon water bottles, cell phone and tablet frames, safety goggles and sunglasses.[91] Having a recycling code or the chasing arrows logo on a material is not an automatic indicator that a material is recyclable but rather an explanation of what the material is. Types 1 and 2 are the most commonly recycled.

This article may be confusing or unclear to readers. (March 2019) |

| Material | Energy savings vs. new production | Air pollution savings vs. new production |

|---|---|---|

| Aluminium | 95%[5][21] | 95%[5][93] |

| Cardboard | 24% | — |

| Glass | 5–30% | 20% |

| Paper | 40%[21] | 73%[94] |

| Plastics | 70%[21] | — |

| Steel | 60%[10] | — |

In addition to environmental impact, there is debate over whether recycling is economically efficient. According to a Natural Resources Defense Council study, waste collection and landfill disposal creates less than one job per 1,000 tons of waste material managed; in contrast, the collection, processing, and manufacturing of recycled materials creates 6–13 or more jobs per 1,000 tons.[95] According to the U.S. Recycling Economic Informational Study, there are over 50,000 recycling establishments that have created over a million jobs in the US.[96] The National Waste & Recycling Association (NWRA) reported in May 2015 that recycling and waste made a $6.7 billion economic impact in Ohio, U.S., and employed 14,000 people.[97] Economists[who?] would classify this extra labor used as a cost rather than a benefit since these workers could have been employed elsewhere; the cost effectiveness of creating these additional jobs remains unclear.[citation needed]

Sometimes cities have found recycling saves resources compared to other methods of disposal of waste. Two years after New York City declared that implementing recycling programs would be "a drain on the city", New York City leaders realized that an efficient recycling system could save the city over $20 million.[98] Municipalities often see fiscal benefits from implementing recycling programs, largely due to the reduced landfill costs.[99] A study conducted by the Technical University of Denmark according to the Economist found that in 83 percent of cases, recycling is the most efficient method to dispose of household waste.[10][21] However, a 2004 assessment by the Danish Environmental Assessment Institute concluded that incineration was the most effective method for disposing of drink containers, even aluminium ones.[100]

Fiscal efficiency is separate from economic efficiency. Economic analysis of recycling does not include what economists call externalities: unpriced costs and benefits that accrue to individuals outside of private transactions[citation needed]. Examples include less air pollution and greenhouse gases from incineration and less waste leaching from landfills. Without mechanisms such as taxes or subsidies, businesses and consumers following their private benefit would ignore externalities despite the costs imposed on society. If landfills and incinerator pollution is inadequately regulated, these methods of waste disposal appear cheaper than they really are, because part of their cost is the pollution imposed on people nearby. Thus, advocates have pushed for legislation to increase demand for recycled materials.[5] The United States Environmental Protection Agency (EPA) has concluded in favor of recycling, saying that recycling efforts reduced the country's carbon emissions by a net 49 million metric tonnes in 2005.[10] In the United Kingdom, the Waste and Resources Action Programme stated that Great Britain's recycling efforts reduce CO2 emissions by 10–15 million tonnes a year.[10] The question for economic efficiency is whether this reduction is worth the extra cost of recycling and thus makes the artificial demand creates by legislation worthwhile.

Certain requirements must be met for recycling to be economically feasible and environmentally effective. These include an adequate source of recyclates, a system to extract those recyclates from the waste stream, a nearby factory capable of reprocessing the recyclates, and a potential demand for the recycled products. These last two requirements are often overlooked—without both an industrial market for production using the collected materials and a consumer market for the manufactured goods, recycling is incomplete and in fact only "collection".[5]

Free-market economist Julian Simon remarked "There are three ways society can organize waste disposal: (a) commanding, (b) guiding by tax and subsidy, and (c) leaving it to the individual and the market". These principles appear to divide economic thinkers today.[101]

Frank Ackerman favours a high level of government intervention to provide recycling services. He believes that recycling's benefit cannot be effectively quantified by traditional laissez-faire economics. Allen Hershkowitz supports intervention, saying that it is a public service equal to education and policing. He argues that manufacturers should shoulder more of the burden of waste disposal.[101]

Paul Calcott and Margaret Walls advocate the second option. A deposit refund scheme and a small refuse charge would encourage recycling but not at the expense of illegal dumping. Thomas C. Kinnaman concludes that a landfill tax would force consumers, companies and councils to recycle more.[101]

Most free-market thinkers detest subsidy and intervention, arguing that they waste resources. The general argument is that if cities charge the full cost of garbage collection, private companies can profitably recycle any materials for which the benefit of recycling exceeds the cost (e.g. aluminum[102]) and do not recycle other materials for which the benefit is less than the cost (e.g. glass[103]). Cities, on the other hand, often recycle even when they not only do not receive enough for the paper or plastic to pay for its collection, but must actually pay private recycling companies to take it off of their hands.[102] Terry Anderson and Donald Leal think that all recycling programmes should be privately operated, and therefore would only operate if the money saved by recycling exceeds its costs. Daniel K. Benjamin argues that it wastes people's resources and lowers the wealth of a population.[101] He notes that recycling can cost a city more than twice as much as landfills, that in the United States landfills are so heavily regulated that their pollution effects are negligible, and that the recycling process also generates pollution and uses energy, which may or may not be less than from virgin production.[104]

Certain countries trade in unprocessed recyclates. Some have complained that the ultimate fate of recyclates sold to another country is unknown and they may end up in landfills instead of being reprocessed. According to one report, in America, 50–80 percent of computers destined for recycling are actually not recycled.[105][106] There are reports of illegal-waste imports to China being dismantled and recycled solely for monetary gain, without consideration for workers' health or environmental damage. Although the Chinese government has banned these practices, it has not been able to eradicate them.[107] In 2008, the prices of recyclable waste plummeted before rebounding in 2009. Cardboard averaged about £53/tonne from 2004 to 2008, dropped to £19/tonne, and then went up to £59/tonne in May 2009. PET plastic averaged about £156/tonne, dropped to £75/tonne and then moved up to £195/tonne in May 2009.[108]

Certain regions have difficulty using or exporting as much of a material as they recycle. This problem is most prevalent with glass: both Britain and the U.S. import large quantities of wine bottled in green glass. Though much of this glass is sent to be recycled, outside the American Midwest there is not enough wine production to use all of the reprocessed material. The extra must be downcycled into building materials or re-inserted into the regular waste stream.[5][10]

Similarly, the northwestern United States has difficulty finding markets for recycled newspaper, given the large number of pulp mills in the region as well as the proximity to Asian markets. In other areas of the U.S., however, demand for used newsprint has seen wide fluctuation.[5]

In some U.S. states, a program called RecycleBank pays people to recycle, receiving money from local municipalities for the reduction in landfill space that must be purchased. It uses a single stream process in which all material is automatically sorted.[109]

This article may be confusing or unclear to readers. (March 2019) |

Critics dispute the net economic and environmental benefits of recycling over its costs, and suggest that proponents of recycling often make matters worse and suffer from confirmation bias. Specifically, critics argue that the costs and energy used in collection and transportation detract from (and outweigh) the costs and energy saved in the production process; also that the jobs produced by the recycling industry can be a poor trade for the jobs lost in logging, mining, and other industries associated with production; and that materials such as paper pulp can only be recycled a few times before material degradation prevents further recycling.[110]

Journalist John Tierney notes that it is generally more expensive for municipalities to recycle waste from households than to send it to a landfill and that "recycling may be the most wasteful activity in modern America."[111]

Much of the difficulty inherent in recycling comes from the fact that most products are not designed with recycling in mind. The concept of sustainable design aims to solve this problem, and was laid out in the 2002 book Cradle to Cradle: Remaking the Way We Make Things by architect William McDonough and chemist Michael Braungart.[112] They suggest that every product (and all packaging it requires) should have a complete "closed-loop" cycle mapped out for each component—a way in which every component either returns to the natural ecosystem through biodegradation or is recycled indefinitely.[10][113]

Complete recycling is impossible from a practical standpoint. In summary, substitution and recycling strategies only delay the depletion of non-renewable stocks and therefore may buy time in the transition to true or strong sustainability, which ultimately is only guaranteed in an economy based on renewable resources.[114]: 21

— M. H. Huesemann, 2003

While recycling diverts waste from entering directly into landfill sites, current recycling misses the dispersive components. Critics believe that complete recycling is impracticable as highly dispersed wastes become so diluted that the energy needed for their recovery becomes increasingly excessive.

As with environmental economics, care must be taken to ensure a complete view of the costs and benefits involved. For example, paperboard packaging for food products is more easily recycled than most plastic, but is heavier to ship and may result in more waste from spoilage.[115]

The amount of energy saved through recycling depends upon the material being recycled and the type of energy accounting that is used. Correct accounting for this saved energy can be accomplished with life-cycle analysis using real energy values, and in addition, exergy, which is a measure of how much useful energy can be used. In general, it takes far less energy to produce a unit mass of recycled materials than it does to make the same mass of virgin materials.[116][117][118]

Some scholars use emergy (spelled with an m) analysis, for example, budgets for the amount of energy of one kind (exergy) that is required to make or transform things into another kind of product or service. Emergy calculations take into account economics that can alter pure physics-based results. Using emergy life-cycle analysis researchers have concluded that materials with large refining costs have the greatest potential for high recycle benefits. Moreover, the highest emergy efficiency accrues from systems geared toward material recycling, where materials are engineered to recycle back into their original form and purpose, followed by adaptive reuse systems where the materials are recycled into a different kind of product, and then by-product reuse systems where parts of the products are used to make an entirely different product.[119]